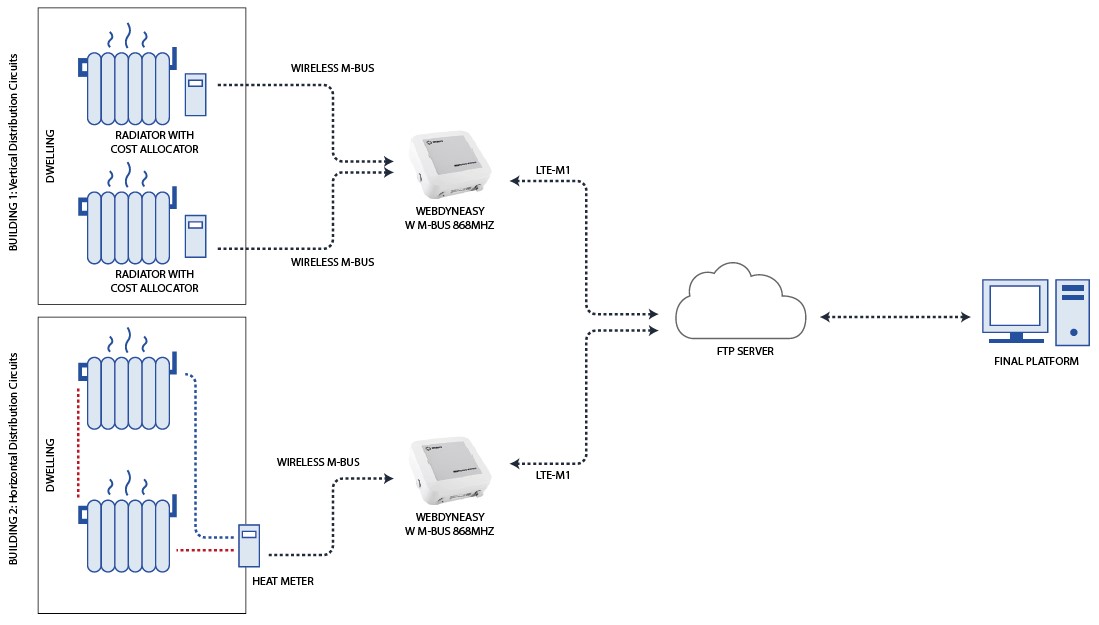

Telemetry of heat cost allocators

Due to the recent European regulations that oblige buildings with centralized heating to carry out an individualized measurement of the energy consumption of their radiators, a new need arises to achieve greater efficiency in this process. To achieve individualized measurement of the consumption of each home, in most cases it is necessary to install eitherheat cost allocators in each radiator (vertical installation) or a heating meter in the pipes that enter the home (horizontal installation). Both devices send the information via Wireless M-bus. To save the staff the trips to the installation, the market is evolving towards intelligent IoT systems that, through the existence of Wireless M-Bus concentrators, collect all the data periodically and transmit it to a server where it will be interpreted by a final platform.

Device: WebdynEasy W M-Bus 868MHz, wireless gateway for metering

Platform: FTP

The heating cost individualization aims to make users aware of their energy consumption by calculating their bills using their actual consumption. This consumption is calculated using devices that determine how much heat or cold is used inside each home. There are currently two main solutions available:

Individual thermal energy meters: individual thermal energy meters are installed. They are placed at the entrance of the houses and are used to measure the amount of heat or cold used directly using Wireless M-Bus. They are used in horizontal installations, and one meter is required for each dwelling.

Heating cost distribution devices: when it is economically feasible and technically possible to install individual meters, heat cost allocators are installed that are placed directly on the radiators. These measure the temperature difference between the radiator and the room and therefore calculate how much heat is used effectively using Wireless M-Bus as well. These devices are specially adapted to buildings with vertical circuits for hot water distribution.

Due to these characteristics, it is necessary to have a Wireless M-Bus concentrator that performs the data collection function in a smart and automated way. This concentrator must also have high penetration cellular connectivity to be able to transmit information to the cloud from facilities in meter rooms or maintenance rooms in large buildings, without losing coverage. In addition, to reduce maintenance costs and facilitate field deployment, it would be interesting if it had a battery and energy autonomy for years as well as IP protection against humidity.

The WebdynEasy W M-Bus 868MHz hub meets these and other requirements by being designed for wireless networks using Wireless M-Bus radio technology on the 868MHz frequency. Its main functions are autonomous data collection from M-Bus wireless meters or sensors. The ease of plug & play installation and remote configuration via Bluetooth BLE allows for immediate field efficiency. This new product works with a battery with autonomy of up to 10 years, with the possibility of also connecting to an external 12V current. For added security, it encrypts the data it collects and sends directly to an FTP. It allows its installation both on a DIN rail and on a wall, and has IP67 protection, which makes it resistant to dust, wind, rain, and other adverse elements in case of being installed outdoors. Its small size makes it ideal for installation in limited spaces where conventional equipment does not fit.

The WebdynEasy W M-Bus 868MHz collects all the information from the heat cost allocators at its fingertips via Wireless M-Bus, stores the data and sends it to the cloud via LTE-M1 in the established connection windows. The data is sent to an FTP server so that the final platform can use it for cost distribution.