Solar self-consumption in a supermarket

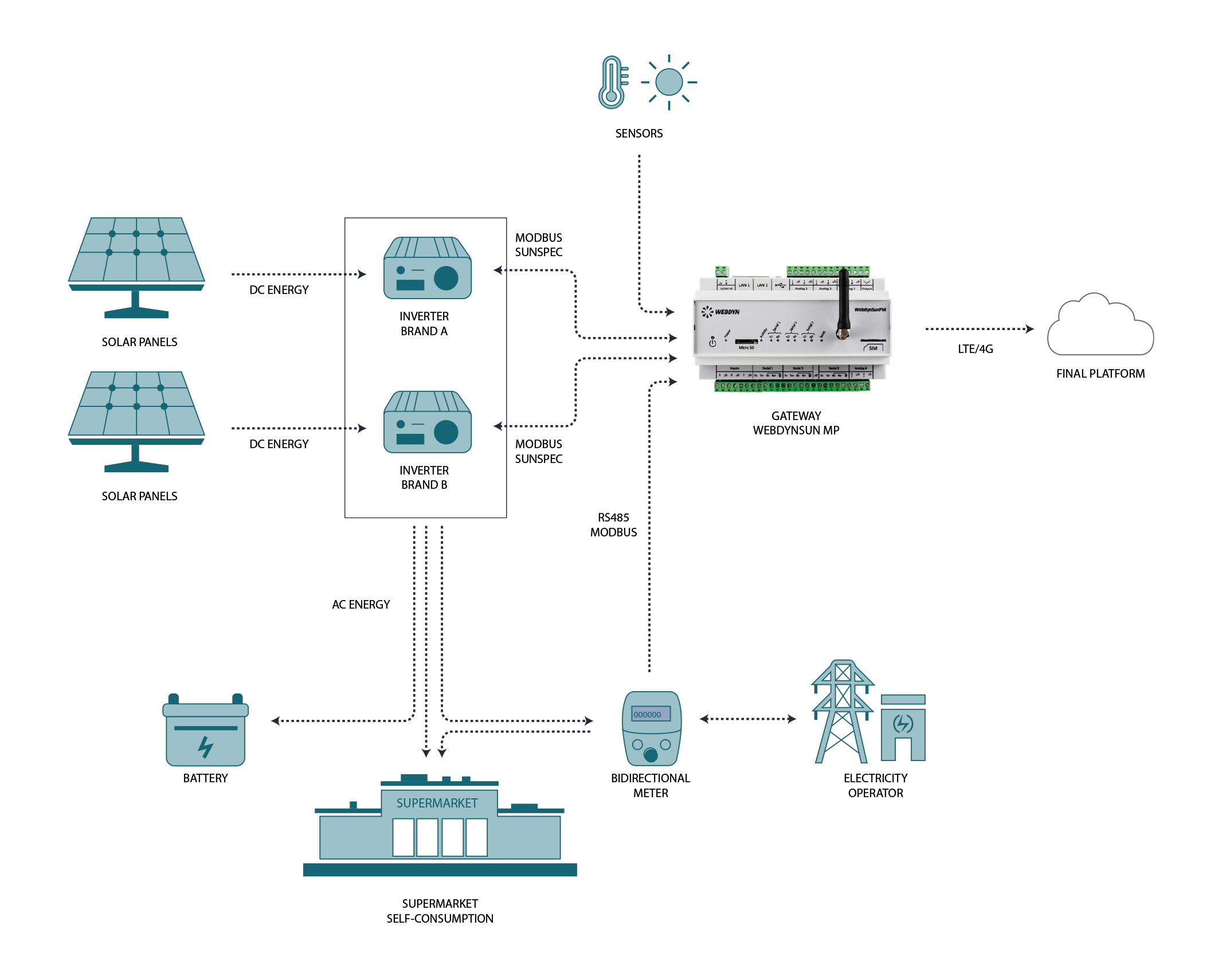

When we face a large solar energy self-consumption installation, the main challenge for its success is to be able to monitor all its devices and to act on them to achieve what we call “zero injection”. This case study consists on controlling the installation by sizing the energy production to fully supply the building (in this case a large supermarket) without suffering an excess of energy that must be poured into the electricity grid.

Device: WebdynsunPM, industrial gateway for Solar Energy

Platform: Any Solar Energy platform

In this kind of large-scale installations, it is especially important to be able to independently read any inverter brand and to communicate with them in order to size the energy production to achieve “zero injection” if necessary. It is also important to be able to control as many inverters as possible, which will allow us to reduce costs. In addition, the installation sensors and the submetering meter should also be monitored with the same connectivity equipment. Finally, it is also important that the information collected by our communication and control devices can communicate in a transparent way with any Solar Energy control platform.

In order to meet these requirements, our proposal for this kind of facility is the WebdynSun PM gateway specialized in Solar Energy. Thanks to its features, all the data from a solar installation can be monitored with a single device.

- Through its digital or analog inputs it can measure the records of the environmental sensors (temperature, sunlight intensity, wind speed…).

- Thanks to its modbus interface it can communicate, with a single gateway, with up to 100 inverters of the main brands on the market.

- Being specialized in Solar Energy, the WebdynSun PM model allows to act on the inverters in case of energy overproduction to avoid injection into the grid and thus achieving “zero injection”.

- Through its RS485 modbus inputs we can obtain the submetering counter readings.

- It works independently with any end platform on the market, without the need to change the installation depending on the management company.

By having the entire installation monitored through a single gateway, its management is simplified and costs are reduced. Furthermore, as it is a device that works independently with the main inverter and end-platform brands, the profitability of the equipment is maximized by not having to change it depending on the different elements of the solution.