Data Center Monitoring

A Data Center is an installation of one or several rooms full of computers and electronic equipment which function as the server of company or an organization, whether it is public or private. These facilities, as well as their features and size, can vary. They can be from large buildings dedicated entirely to this function, to small rooms within the organization’s facilities. However, all of them have in common the need for constant monitoring, in real time and at different levels, to ensure the proper functioning of the equipment inside and that the conditions of the rooms are the most suitable for the maintenance of the devices.

Device: MTX-Router-Titan II, advanced industrial router with RS485, Modbus and Ethernet

Platform: Cervello IoT Platfotm

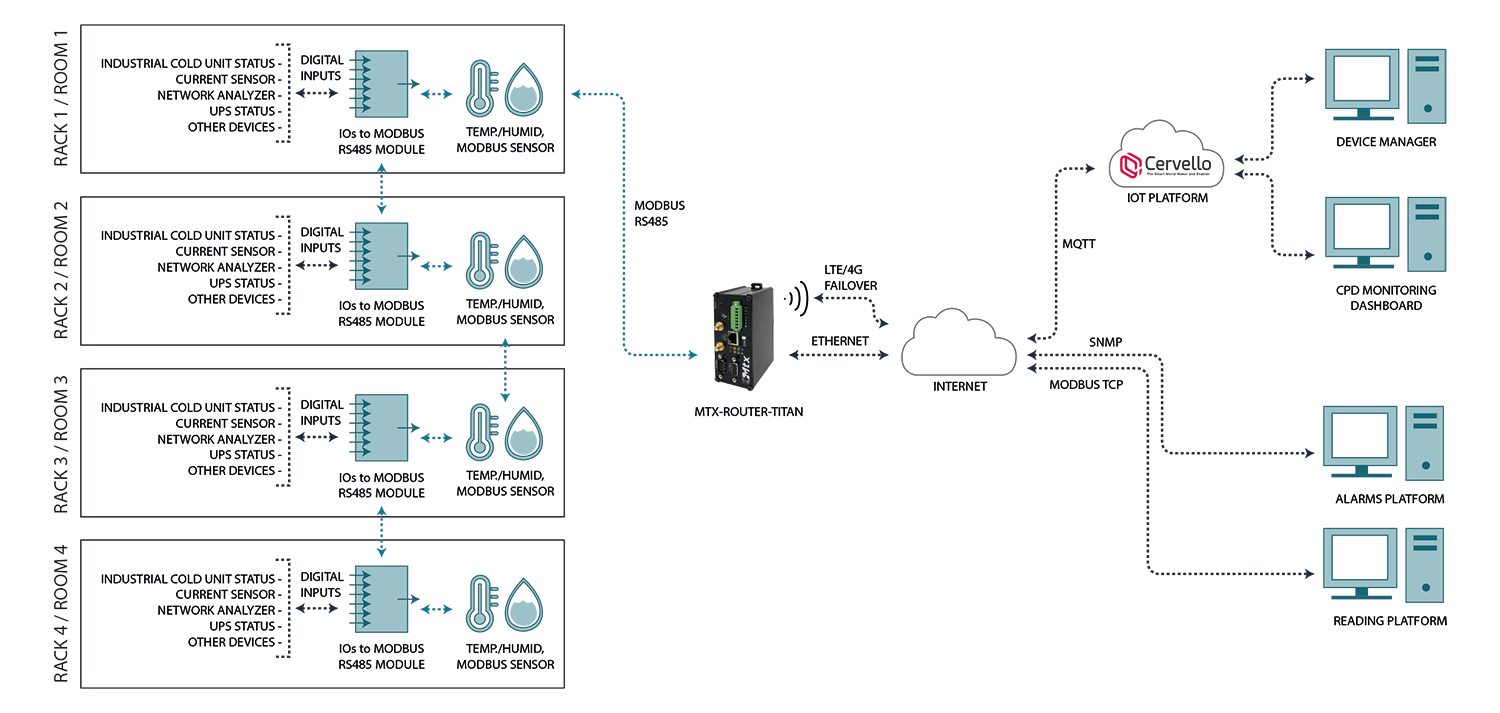

In an example of a typical installation we find a building with four Data Center rooms with some variables we want to monitor. The data of these variables is sent by sensors and connectivity devices in the room controlling the temperature and humidity of the equipment in the room. Our solution is organized in four rooms, each one with a modbus temperature and humidity sensor and a connectivity module with up to 16 digital inputs and modbus output to which the sensors and the equipment are connected: an industrial cold unit, a network analyzer, UPS, sensors or any other device with digital output.

In terms of connectivity, since the rooms have a permanent internet connection, internet connectivity via Ethernet is established as the main means of communication. However, for the solution to continue working in the event of a network crash, it is necessary that the connectivity device can also access the network using LTE/4G technology.

Given these interface needs and with the requirement of significant processing capacity, the solution is designed around an MTX-Router-Titan II, an industrial router with high processing performance, RS485 Modbus connectivity and output via Ethernet or LTE/4G with different protocols.

The MTX-Router-Titan II performs a continuous polling of all Modbus RTU sensors connected to the RS485 bus to manage Data Center rooms. Each time a change in the registration of any sensor is detected, the MTX-Router-Titan II sends an alarm message to an SNMP Platform informing of such change or in case of reading failures (for example, power failure of the sensors) At the same time, the modbus registers of the sensors must also be read at any time from the SNMP Platform to check, in real time, the status of any of the devices connected to the solution.

On the other hand, always in parallel to the previous SNMP functionality, the MTX-Router-Titan II maps the modbus registers read from the sensors in its own internal memory to be able to act as a Modbus TCP slave and allow a reading platform to access via modbus to read the records stored directly from the internal memory of the equipment.

Finally, the MTX-Router-Titan II sends all the information, both modbus readings and the information itself, through MQTT to the Cervello Device Manager, which can act with both the Device Manager function for the management, control and monitoring of the devices, as well as with the Data Center Monitoring Platform function, allowing to visually display all the information of each of the sensors and records obtained in each of the CPD rooms on a personalized dashboard.

Thanks to this solution, remote monitoring of a Data Center center can be carried out, regardless of its size and configuration, in a simple, practical and efficient way, improving the efficiency of the maintenance of the facilities and increasing safety.