Industrial Cooling Unit Monitoring

In an increasingly global industrial sector in which companies aspire to sell their products worldwide, a remote monitoring, support and technical assistance system is essential to alleviate the costs of breakdowns and guarantees having thousands of kilometers of distance between the main headquarters and the installed equipment. A clear example of this: the companies dedicated to Industrial Cold, whose refrigeration units tend to be installed in any industry in the world, making prevention and remote monitoring the key to saving costs.

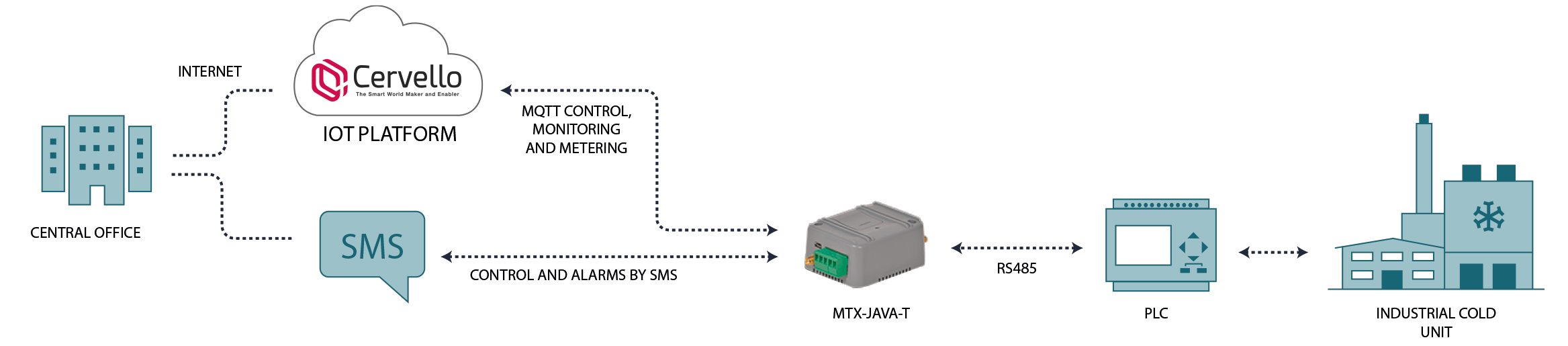

Device: MTX-Java-T, basic programmable modem with RS485 and RS232

Platform: Cervello IoT Platfotm

In these cases, the industrial refrigeration units are connected to a PLC that collects all the parameters sent by the equipment, stores them and sends them periodically thanks to the connectivity of an MTX device. The parameters sent collect information on consumption, outdoor temperature and some internal details regarding the status of the unit, such as an error log, the usage of certain components or the date of future revisions.

This PLC normally has an RS485 output, so the device necessary to achieve the solution must be economical, with RS485 and 4G / 3G / 2G connectivity (in order to cover all types of coverage regardless of the final destination). Due to these requirements, the solution is designed with an MTX-Java-T, a basic modem with an adjusted price, 4G / 3G / 2G connectivity and an RS485 input.

The data received by the MTX-Java-T is sent by MQTTs to the IoT Cervello platform, which transforms the information, stores it and allows it to be displayed graphically through different tables or graphics in the visual dashboard of the platform.

In addition to the data collected and sent periodically, the MTX-Java-T, thanks to its MTX-Tunnel firmware, allows the execution of commands that can directly and in real time request a specific data from the PLC. This can be done both from the Cervello IoT platform itself, and by simple SMS from an authorized telephone number. To add more intelligence, thanks to the MTX-Tunnel, it can also be managed that if a certain value of a selected variable leaves an established range, an alarm is sent directly via SMS.

Thanks to all this information, control and alarms carried out remotely, industrial refrigeration companies can reduce their warranty repair costs thanks to the forecast or even access to the error log of all their equipment installed around the world.